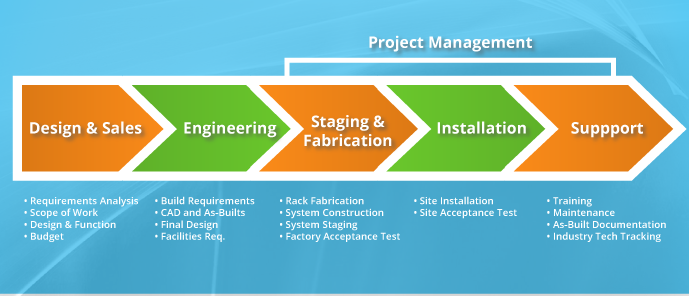

Five Steps to Project Success

We have developed a five-step process (Design, Engineering, Staging & Fabrication, Installation, and Support) to create integrated systems that just work. We ensure the recommended system design, functional specifications, operational characteristics, facility requirements and implementation will meet or exceed your expectations. Our process provides the highest degree of quality, reliability and efficiency for complex systems and helps Integrated Media Systems successfully support clients nationally and globally.

Design/Sales

During the Design/Sales Phase, we work with clients to identify the functional and technical requirements for the audiovisual system, as well as the facility. We then create the System Design and Scope of Work documents to ensure the identified requirements are reflected in the final solution. We will detail the work to be performed, the expectations that need to be met, a functional definition of how the systems will perform, and test plan along with the budget and the time frame required to provide the solution.

Engineering

Detailed system and facility analysis take place during the Engineering Phase. AutoCAD and VidCAD drawings reflect the system and facility infrastructure construction requirements. The system documentation is finalized and includes the critical milestones, scheduling, system requirements and client expectations. The IMS Build Team will use this documentation to fabricate and install the system. Any final revisions to the design are communicated with the client and then Staging and Fabrication process begins.

Staging & Fabrication

The Staging & Fabrication Phase includes equipment ordering, tracking and receipt, rack fabrication and wiring, programming and system pre-testing as well as factory acceptance testing (FAT) before the equipment is shipped to the installation site. All of the rack fabrication, system construction and pre-wiring are completed in our state-of-the-art Interoperability Lab in order to identify and resolve any fabrication, programming or functional issues before the system is shipped.

The system programming is written in parallel with the fabrication process to make the equipment fully functional during the staging process — including the controls, touch panel and device programming. Once the system set-up is complete in our lab, we test the system for technical continuity, and then test again for Factory Acceptance. Quantitative and qualitative test results are recorded and included as part of the project documentation. IMS welcomes our clients to be present during the factory acceptance testing to observe and confirm the functionality of the system.

The assigned IMS project manager is actively engaged during this phase and is continuously involved until the project is complete. The project manager’s responsibilities during the Staging and Fabrication Phase include project tracking and regular reporting, coordination with related trades and team members and verification of site infrastructure and preparedness prior to installation, scheduling and briefing of installation crews and installation logistics.

Installation

Site installation is performed by a team of engineers, project managers and installation technicians, as required. The installation team is prepared and equipped to perform all necessary work on site. The project manager is also authorized to apply all required resources and to immediately resolve any problems that might arise during the installation process, and reports to the IMS senior management team on the progress of the project.

Upon completion of the installation, a site-acceptance test and system training is performed to ensure complete satisfaction.

Support

IMS is committed to ensuring our clients obtain the maximum return on their investment by working together to adapt the installed technology into your normal business model. We provide complete system documentation, including on-site system training, “Quick-Start” guides, full system as-built AutoCAD drawings, as well as control system, touch panel and device program codes. We continually monitor manufacturer service bulletins and employ our experiential evaluation of systems to be aware of necessary firmware updates that can mitigate potential device failures, increasing system reliability and operational up-time.

IMS can also customize a maintenance service program to fit each individual need for preemptive and standard repair of devices.

714-579-4100

714-579-4100